- Overview

- Product Description

- Feature

- Detailed Photos

- Product Parameters

- Packaging & Shipping

- Feedback from our customers

- Company Profile

- Q&A

Basic Info.

Product Description

The tandem press brake is a machine capable of bending thin plates. Its structure mainly includes bracket, workbench and clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressure plate. The base is composed of seat shell, coil and cover plate, the coil is placed in the depression of the seat shell, and the top of the depression is covered with a cover plate. When in use, the wire is energized to the coil, and after energization, an attractive force is generated on the pressure plate, so as to realize the clamping of the thin plate between the pressure plate and the base.

- Germany Bosch Rexroth integrated hydraulic valveblock, hydraulic tramsmission with high reliability, integrated hydraulic system can effectively alleviate prob-lems caused by leakage of hydraulic fluid.

- American world famous brand for hydraulic pump per-forms well and provides great power for the whole hydraulic system.

- German famous brand motor improves the lifespan ofthe machine and keeps the machione working in lownoise environment.

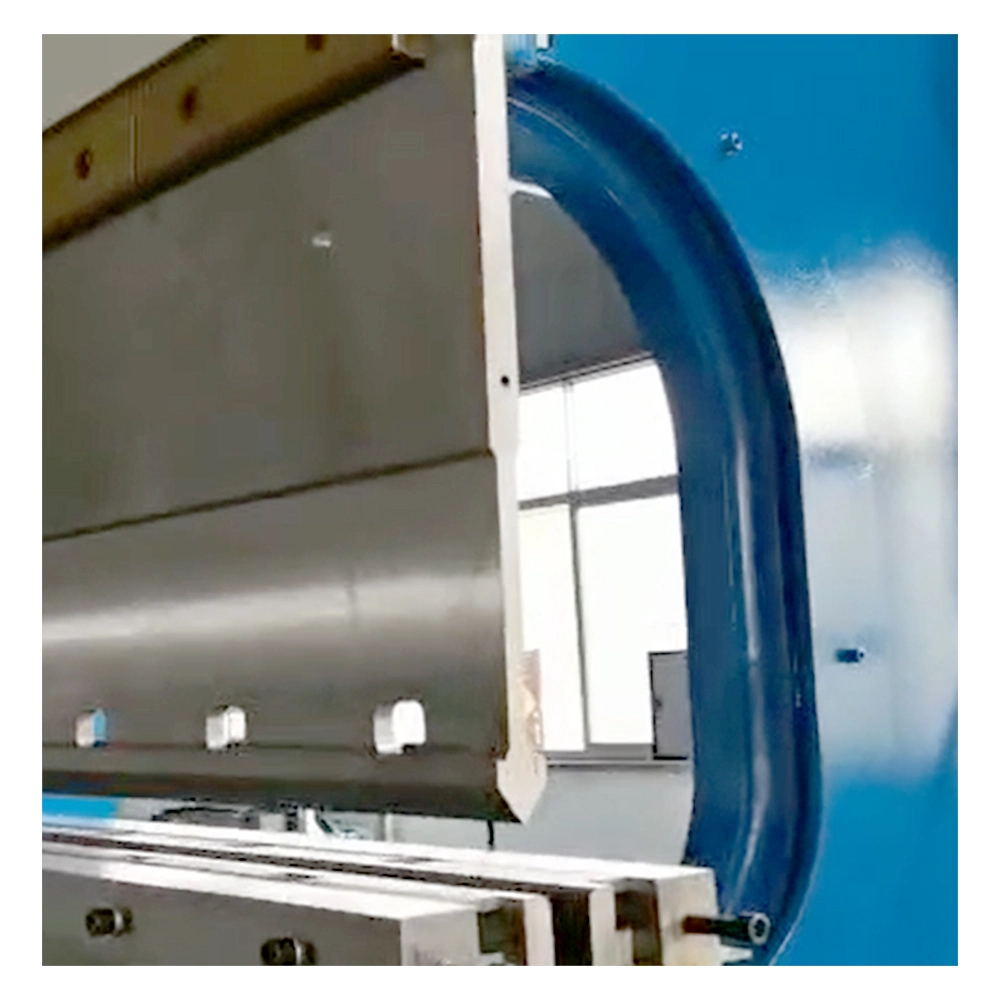

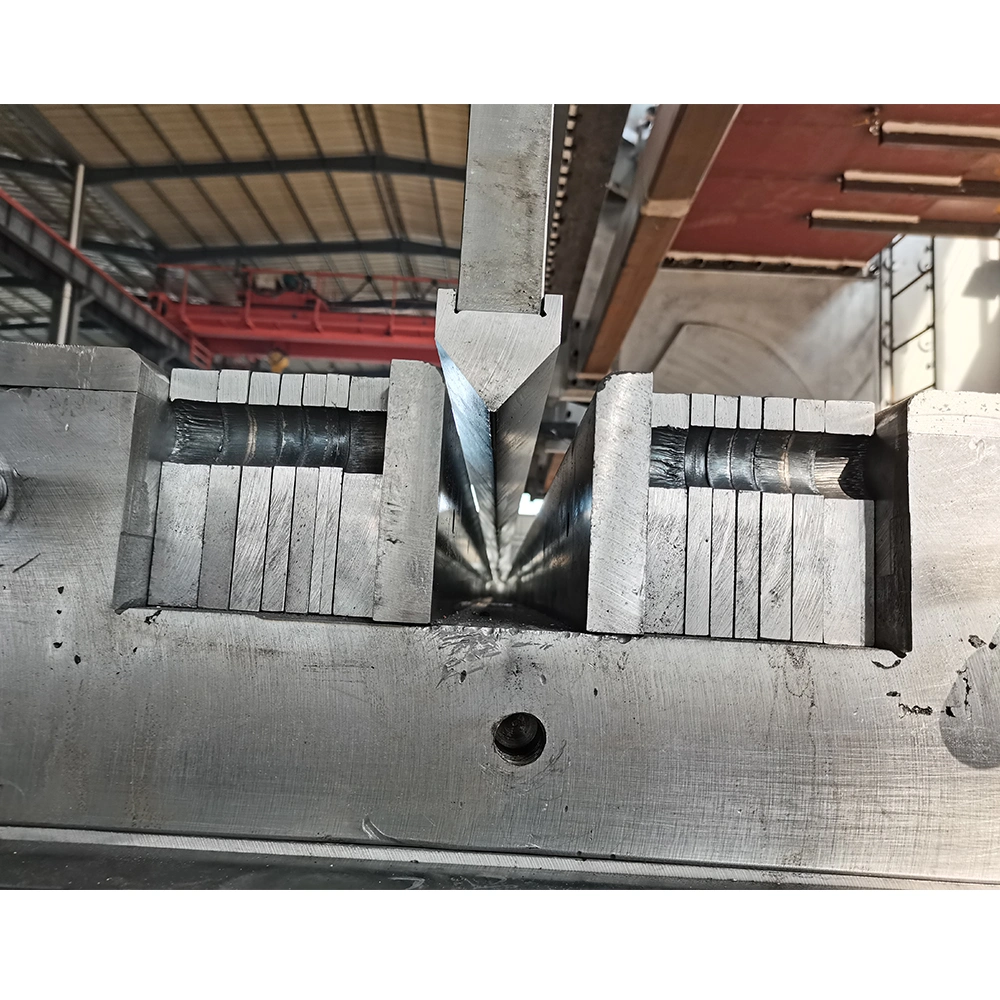

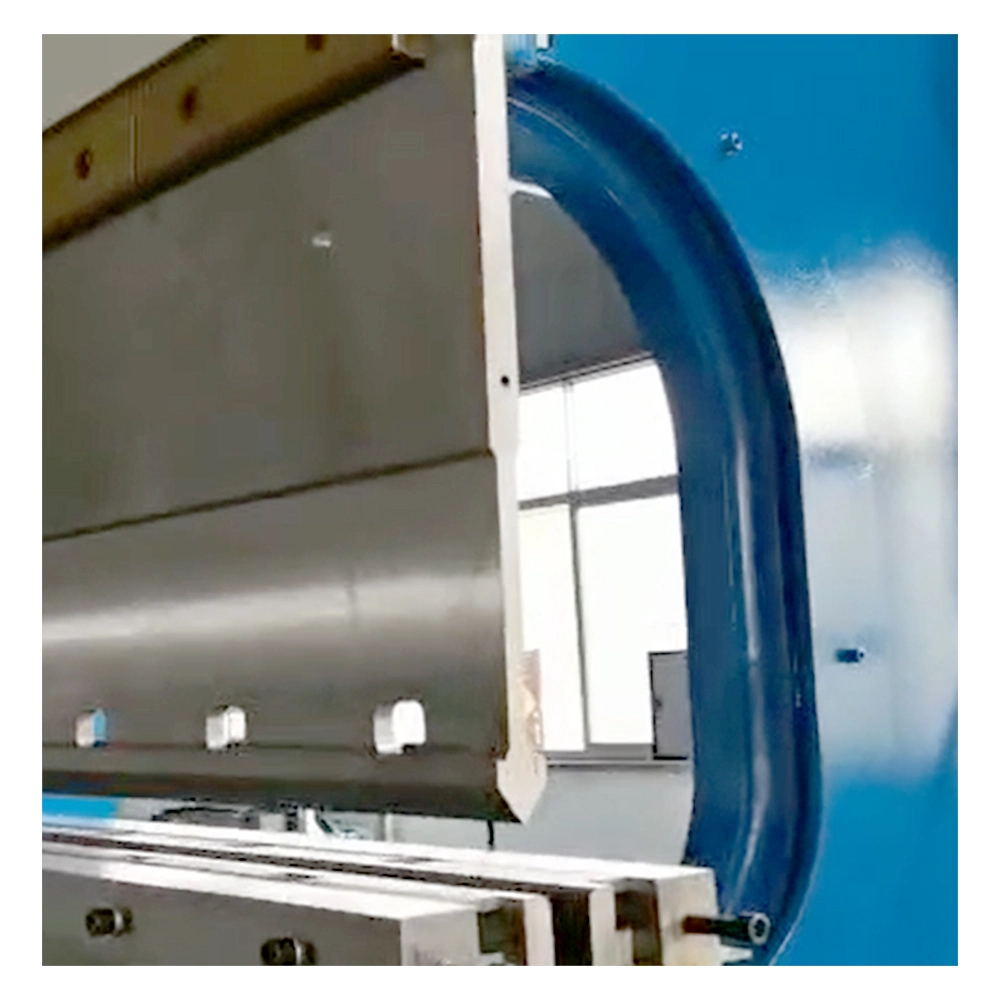

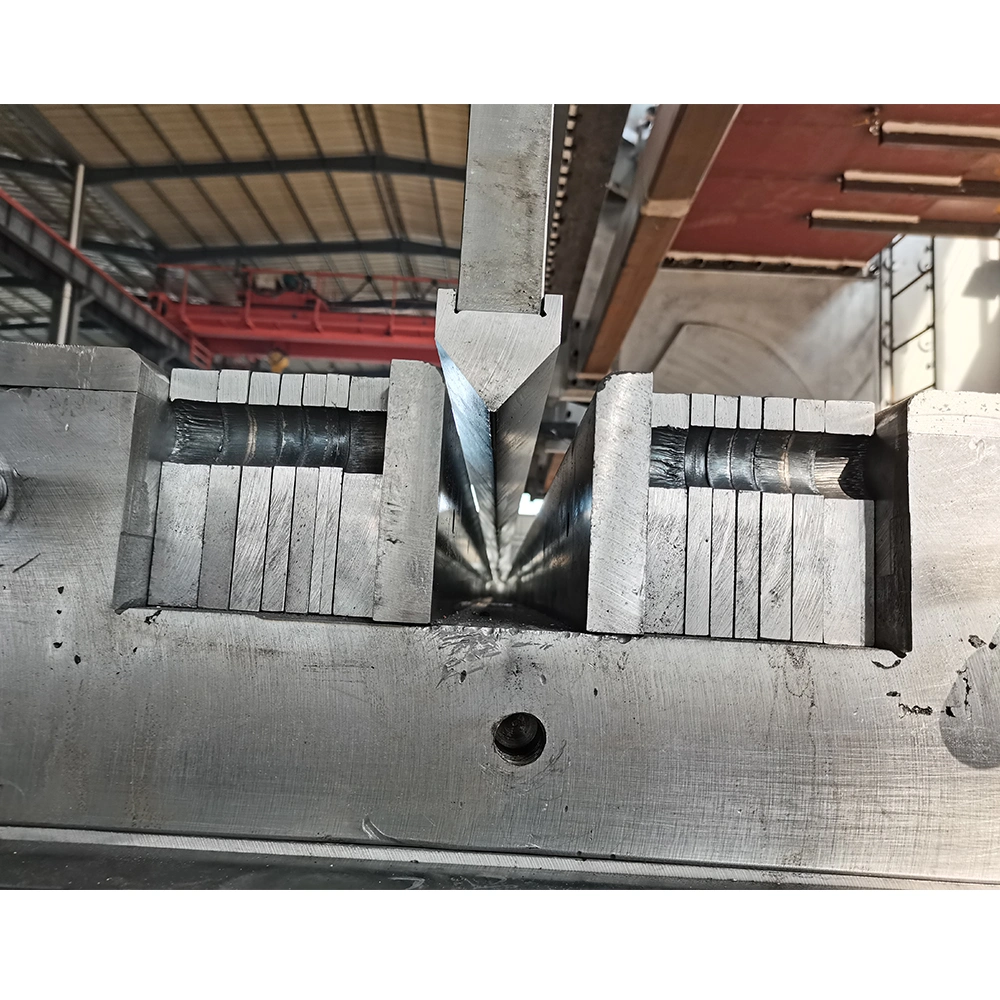

Partial schematic diagram of light pole equipment

Specializing in the production of various mold displays: street light poles, communication poles, power pole equipment manufacturing

Specializing in the production of various mold displays: street light poles, communication poles, power pole equipment manufacturing

| Model | 2-200/6000 | 2-300/6000 | 2-300/7000 | 2-400/7000 | 2-500/7000 | 2-600/7000 | 2-800/7000 | 2-1000/7000 | 2-1200/7000 | 2-1600/7000 | ||

| (KN) Nominal pressure | 2x2000 | 2x3000 | 2x3000 | 2x4000 | 2x5000 | 2x6000 | 2x8000 | 2x10000 | 2x120000 | 2x160000 | ||

| (mm) length o Table | 2x6000 | 2x6000 | 2x7000 | 2x7000 | 2x7000 | 2x7000 | 2x7000 | 2x7000 | 2x7000 | 2x7000 | ||

| (mm) throat Depth | 400 | 650 | 650 | 750 | 800 | 1000 | 1100 | 1100 | 1100 | 1500 | ||

| (mm) Slide stroke | 200 | 250 | 250 | 250 | 320 | 300 | 400 | 400 | 400 | 450 | ||

| (mm) open Height | 560 | 770 | 770 | 810 | 810 | 1000 | 1100 | 1100 | 1100 | 1400 | ||

| (KW) Motor power | 2x15 | 2x22 | 2x22 | 2x22 | 2x30 | 2x30 | 4x22 | 4x30 | 4x30 | 4x55 | ||

L*W*H(mm) | 2*6000 2050 3200 | 2*6000 2450 4380 | 2*7000 2580 4800 | 2*7000 2675 4900 | 2*7000 27000 5000 | 2*7000 2930 6280 | 2*7000 3000 7500 | 2*7000 3100 7500 | 2*7000 3300 7600 | 2*7000 3700 8100 | ||

| (kg) Machine weight | 2x20000 | 2x35000 | 2x40000 | 2x50000 | 2x60000 | 2x65000 | 2x80000 | 2x100000 | 2x130000 | 2x230000 | ||

About US

Shandong Raintech Group is a professional manufacture for CNC machines in metal working with more than 15 years' experience. The factory established in the year of 2008, has been devote to the research and production of the advanced CNC machines which can save the production cost and time in steel industry application

our machines widely used in steel tower transmission, steel structure , bridges, highway , automobile, electrical iron fittings, wind power machines, traffic railway construction , three -dimensional parking system, central air conditioner system, sea water desalination, Petroleum and petrochemical , construction machinery, project machinery and port machinery , Modern granary, shipbuilding etc.

Our brand reputation in advanced leading position in the field domestic, also becoming an important role on international market, the products have been exported to more than 20 countries and area in the world.

The company pay great attention on the technique research and quality, have own many patents on many products depends on our plenty experience in research and management of manufacturing. After these years effort, we gain many patents on our machines design and control systems

Our machines realize the multifunction and multi-process automatic continuously production, through fully automatic functions including detection, infeed and outfeed, processing, stacking, data control etc. and additionally data collection and organization. We have been developed to be an digitized, intelligent, BNR , integrated and high efficiency green manufacture.

Our main products including :

CNC machines for tower &steel structure : CNC angle steel punching , shearing, marking line, CNC flat bar punching, shearing and marking line, CNC high speed gantry moveable drilling machines; CNC H beam drilling machines ; Combined punching, marking and cutting line for flat steel, angle bar and channel steel , CNC band sawing machine etc.

Cold roll forming machines : highway guardrail, automobile bumpers, Truck beam, construction metal section, purlins, roof , wall, decking floor, solar structure , cable tray, storage racks etc.

Metal coils processing lines and tube mill line : Cut-to-Length lines, Slitting lines, Tension Leveling lines and Precision Leveling machines, SS tube mill ERW tube line etc.

Hydraulic press brake machine,Hydraulic plate Shearing machine,Hydraulic plate rolling machine,etc.

We know well that our high reputation among the clients and users based on stable quality and sincerely after-sales service. We will keep devote to provide the great support for the clients from all over the world. Welcome all the partners and users from all over the world cooperate with us!

1.Q: What is the minimum order quantity?

A: 1PCS.

2.Q: What are the payment terms?

A: L/C; T/T or other.

3.Q: How long is the delivery time?

A: 30 Days.

4.Q:How long is the warranty period?

A: 1 Years.

5. Q:Are you factory?

A: Yes. We accept to visit our factory before placing an order for our cnc machines.