Basic Info.

Surface

Hot Dipped Galvanized

MOQ

100 PCS

Transport Package

Wooded Box

Specification

As custom request

Trademark

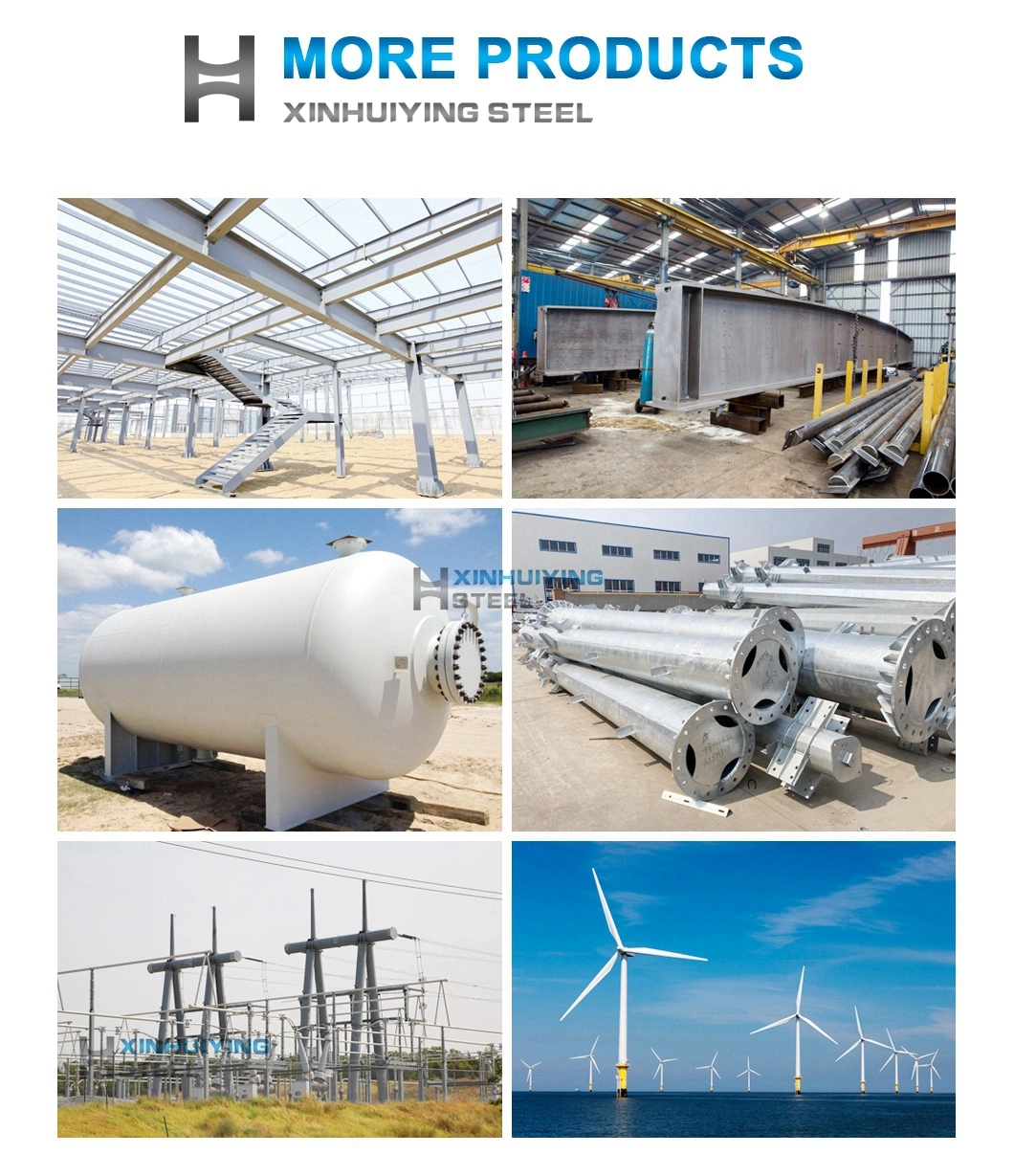

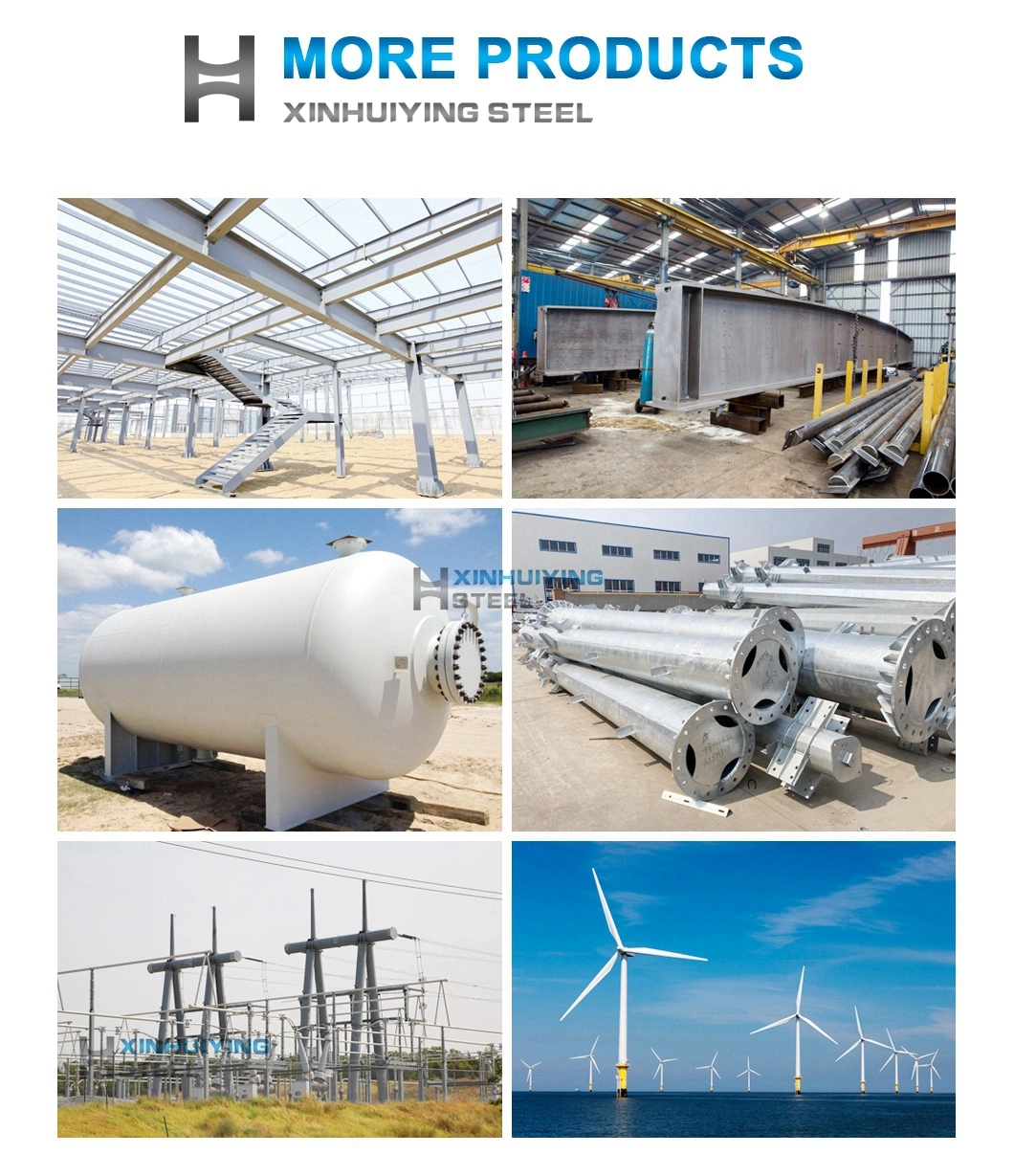

Xinhuiying Steel

Origin

Qingdao China

HS Code

73089000

Production Capacity

10, 000PCS Per Week

Product Description

Sheet metal fabrication laser cutting process

Our full-service fabricators have extensive experience when it comes to metal plate fabrication and meeting your specifications. Our process includes:

Cutting

we also offer laser cutting of mild steel, aluminium, stainless steel, rubber, timber and plastic. We are capable of cutting steel up to 20mm thick, aluminium to 6mm and stainless steel to 16mm. We offer turret punching up to 6mm sheet thickness.

Bending

We offer a variety of metal bending services to both the residential and industrial sectors. Our metal forming services include the bending and rolling of tube and pipe sections and other sheet metal bending services. In addition to bending metal, we also manufacture steel products like fences, gates and balustrades and can provide sheet metal bending for whatever your needs might be.Working from our modern, fully equipped workshop in Qingdao, our metal bending machine produces high-quality results, and our knowledgeable, creative and experienced tradesmen deliver work of the highest standard no matter what size or scale the job.

Rolling

Our qualified and experienced tradesmen can roll a variety of structural shapes and do heavy-duty plate rolling if required thanks to our fully-equipped, modern workshop. Our workshops are equipped with state-of-the-art metal rolling machines, and are outfitted to handle any number of different shapes and sizes, depending on your requirements.

Our full-service fabricators have extensive experience when it comes to metal plate fabrication and meeting your specifications. Our process includes:

Cutting

we also offer laser cutting of mild steel, aluminium, stainless steel, rubber, timber and plastic. We are capable of cutting steel up to 20mm thick, aluminium to 6mm and stainless steel to 16mm. We offer turret punching up to 6mm sheet thickness.

Bending

We offer a variety of metal bending services to both the residential and industrial sectors. Our metal forming services include the bending and rolling of tube and pipe sections and other sheet metal bending services. In addition to bending metal, we also manufacture steel products like fences, gates and balustrades and can provide sheet metal bending for whatever your needs might be.Working from our modern, fully equipped workshop in Qingdao, our metal bending machine produces high-quality results, and our knowledgeable, creative and experienced tradesmen deliver work of the highest standard no matter what size or scale the job.

Rolling

Our qualified and experienced tradesmen can roll a variety of structural shapes and do heavy-duty plate rolling if required thanks to our fully-equipped, modern workshop. Our workshops are equipped with state-of-the-art metal rolling machines, and are outfitted to handle any number of different shapes and sizes, depending on your requirements.