Basic Info.

Model NO.

AD-AHP

Level

A

Application

Interior & Exterior Decoration

Aluminum Alloy

Aluminum Alloy 5052/3003

Temper

H24

Edge Processing

Edge Closed or Edge Open

Adhesive

Bio-Component Modified Epoxy Resin

Foil Thickness

0.04mm, 0.05mm, 0.06mm, 0.07mm

Panel Coating

Roller Coated, PE Coated, Powder Coated

Coating Color

Pure White, Metallic Color, Ral & Pantone Color

Special Color

Wooden Grain and Stone Grain

Transport Package

Standard Export Package-Wooden Crate

Specification

Width: up to 2000mm, Length: up to 16000mm

Trademark

ARROW DRAGON

Origin

China

HS Code

7606119090

Production Capacity

30000sqm/Month

Product Description

Company Introduction

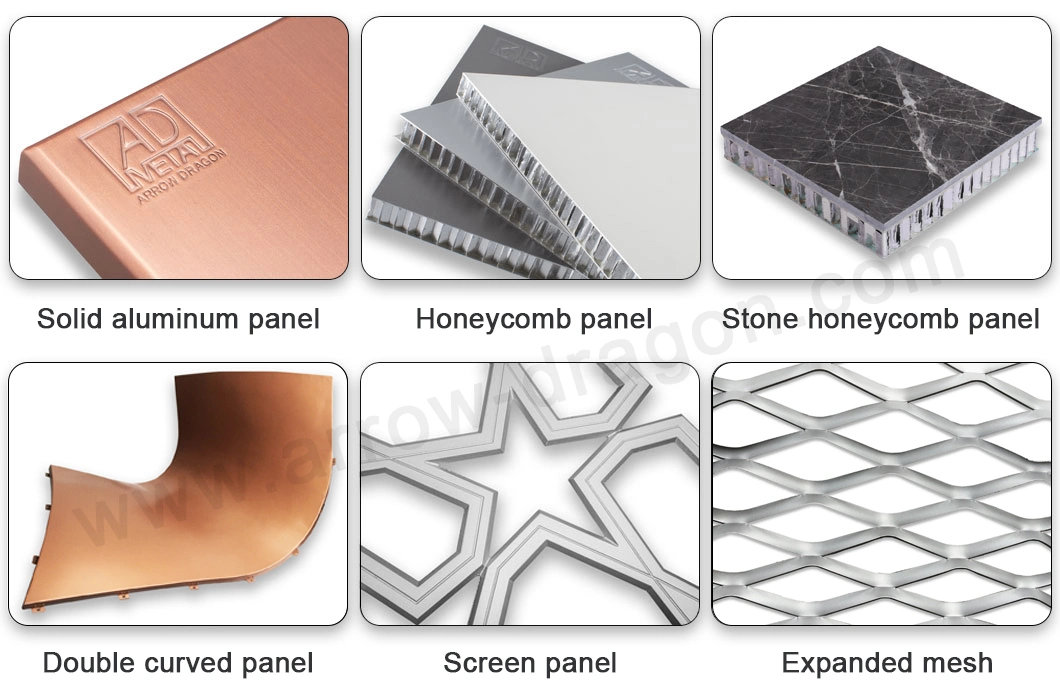

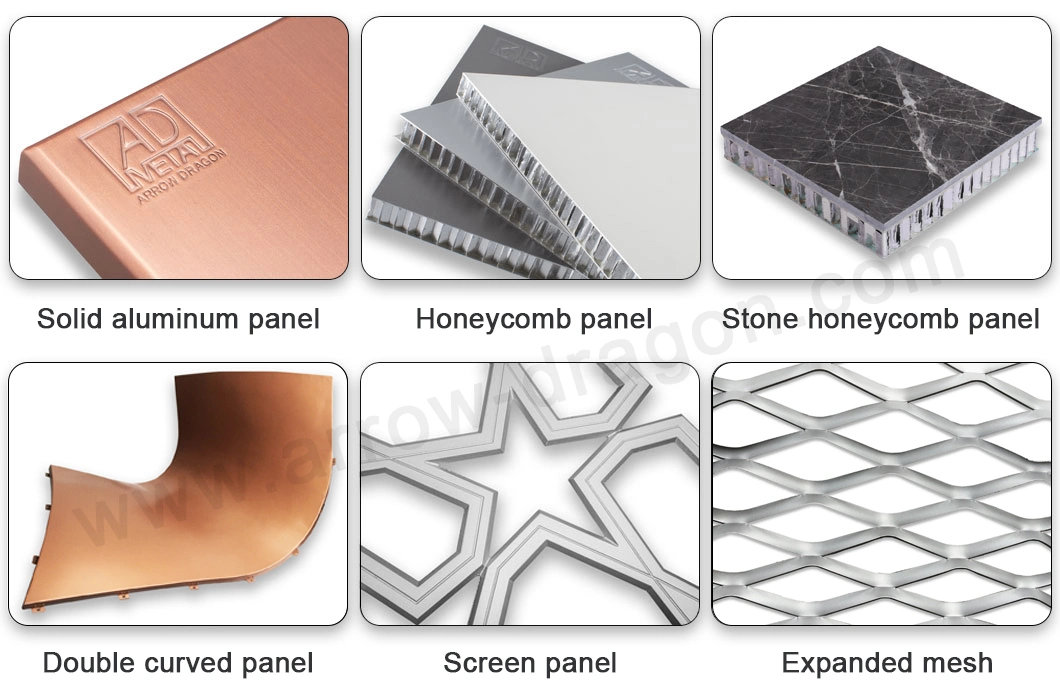

Arrow Dragon Metal Products Co., Ltd specializes in aluminum panels, including regular wall panels (solid aluminum panels, perforated/laser cut panels), curved panels (single curved/double curved/twisted panels), honeycomb panels (aluminum/stone aluminum honeycomb panels), expanded mesh, screen panels, and honeycomb core (aluminum/s.s./mild steel honeycomb core). Due to our outstanding metalwork and stable coating quality, our products have been approved by architects and used in many big projects (pls find it in below Projects Reference).

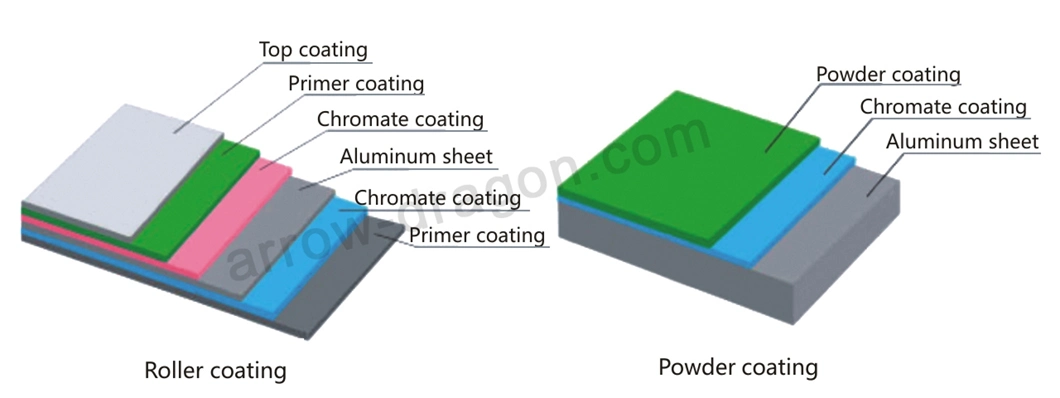

Aluminum honeycomb panels are made of high-quality aluminum plates, and apply roller coating/powder coating on the surface, the panels can be prevented color fading and corrosion from UV, high temperature, humidity, and atmospheric erosion.

Our 6 Main Products

Specification of Aluminum Honeycomb Panel

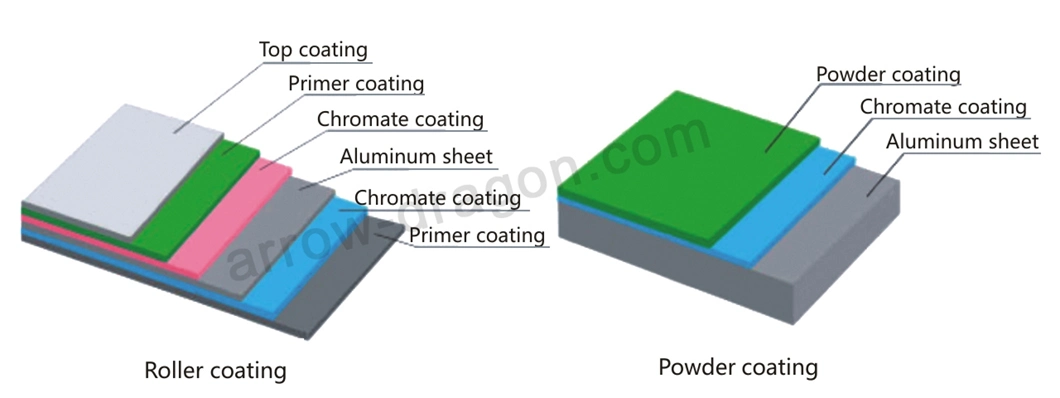

Coating Layer Composition of Roller Coating and Powder Coating

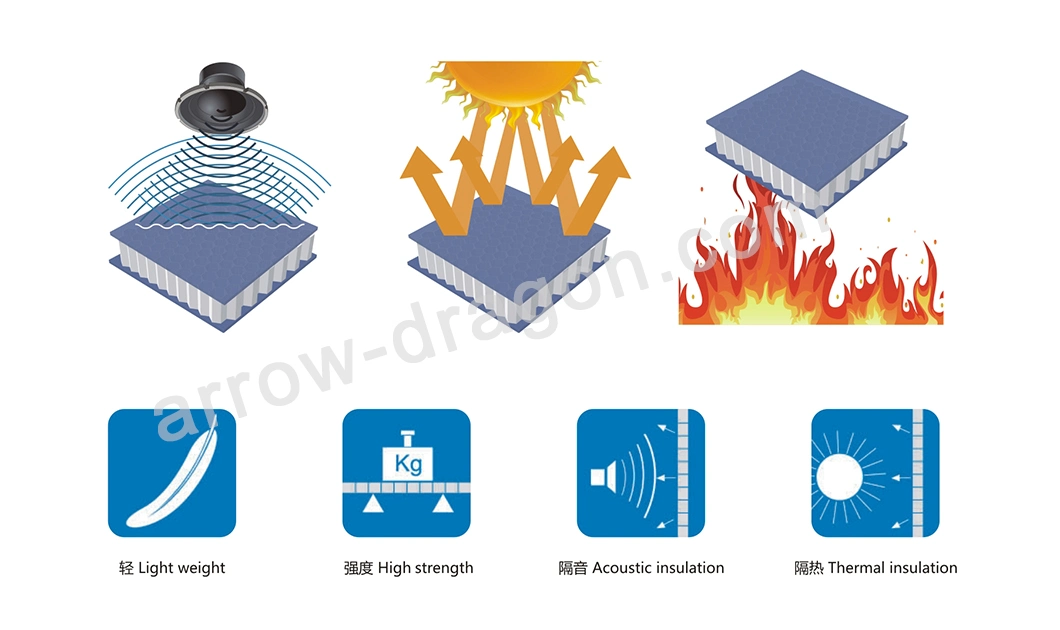

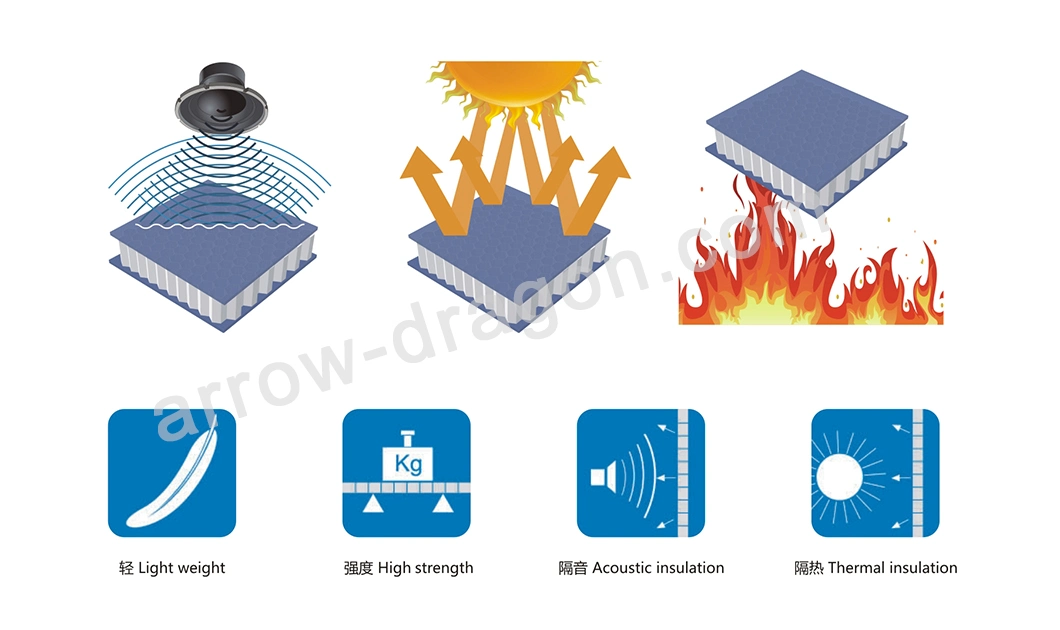

Features of Aluminum Honeycomb Panel

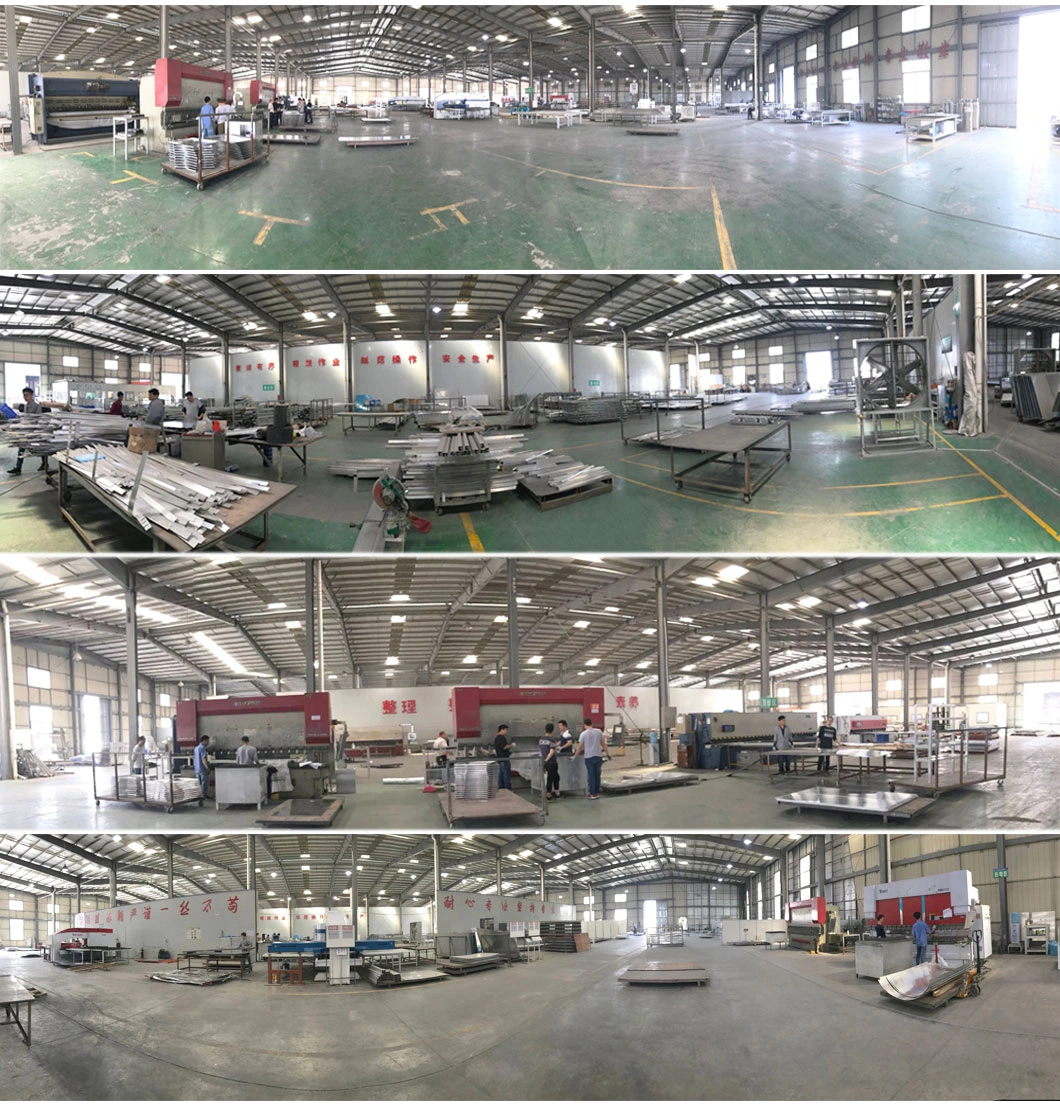

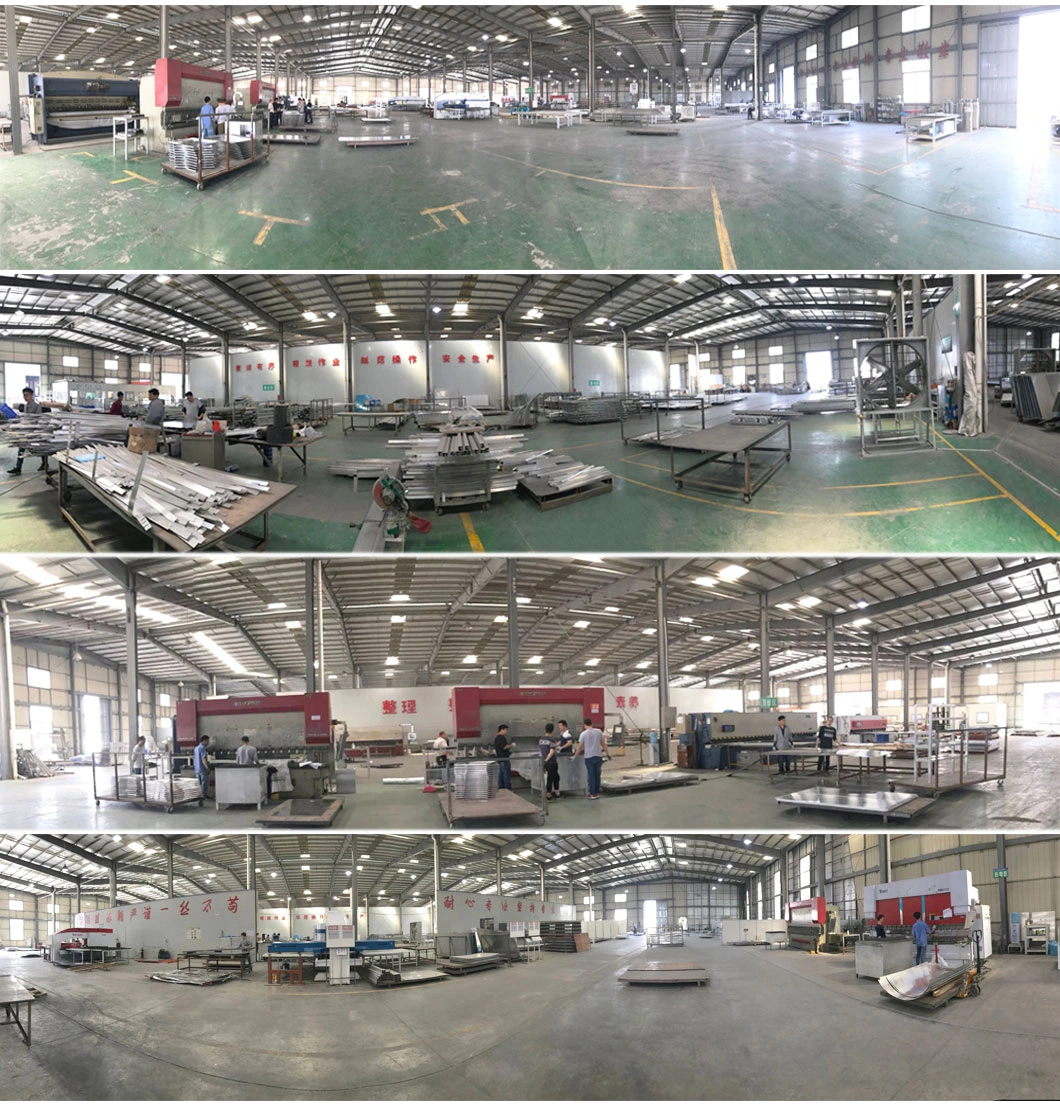

Workshop Show

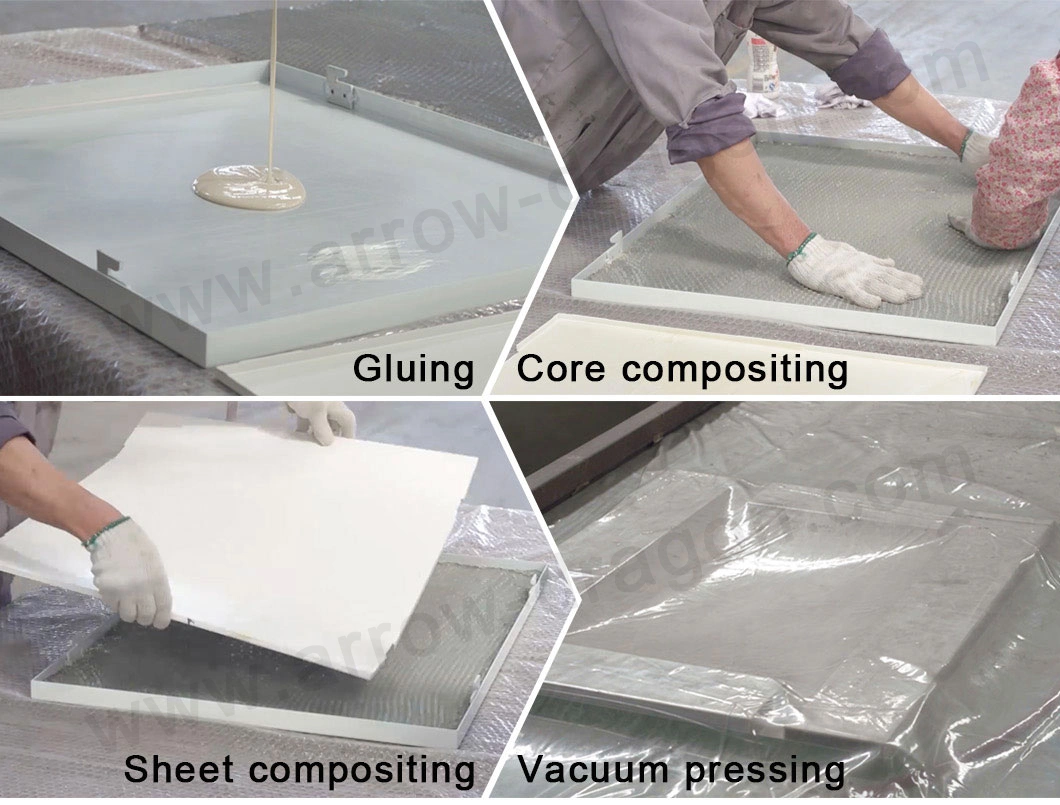

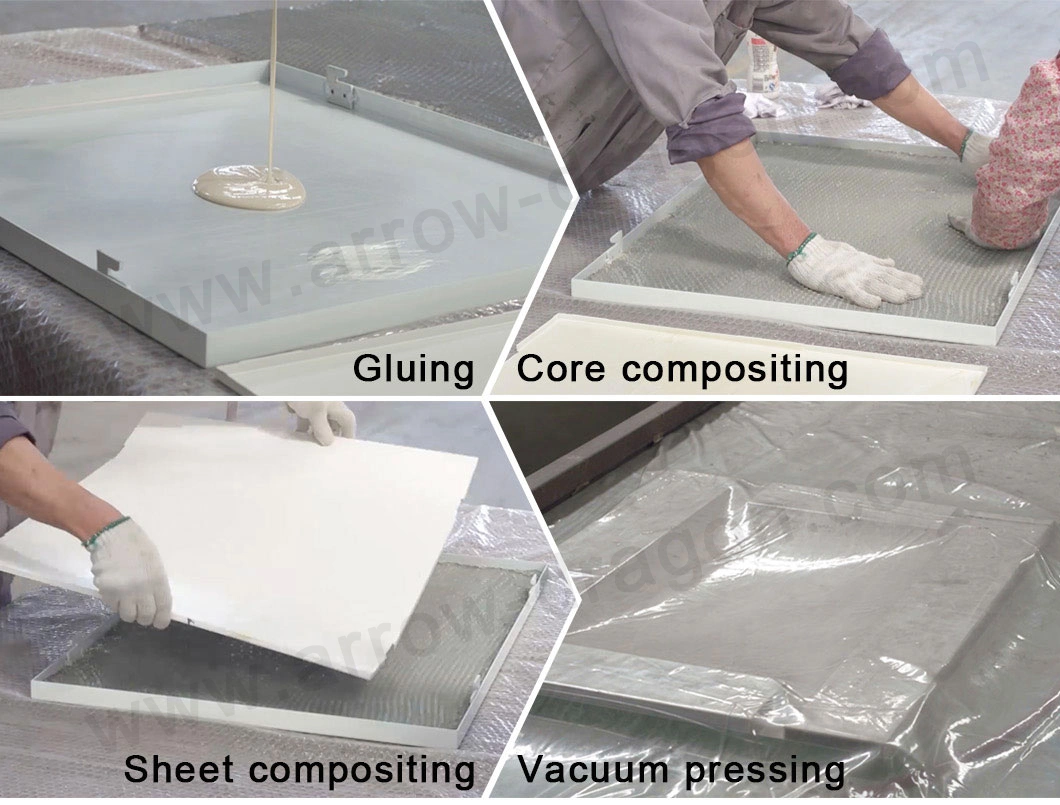

Production Procedure

Sheet metal procedure

Cutting/Shearing - Punching - Arcrolling - Bending - Welding - Burnishing - Rib Assembling - Rivet Assembling - Polishing - Spray Coating.

Spray coating procedure

Hanging - Skim - Alkali - Elimination (by acid) - Chromizing - Drying - Spraying Coating - Baking - Inspection.

Compositing procedure

Gluing - Core Compositing - Sheet Compositing - Vacuum Pressing

Package & Delivery

Application

Aluminum honeycomb panels are widely used in our daily life, not only in architecture area but also in transportation and other areas.

Architecture areas:

Used for architecture: curtain wall, façade cladding, ceilings, roofing, soffit, and column cover of the buildings.

Transportation areas:

Used for cruise ships, fast ferries, luxury marine, yachts and other special vessels.

Used for the rail vehicle, lorry, cabins, and flap systems.

Other areas:

Used for the cleanroom, lightweight containers, carbines for the machine tool, wind tunnels, and lifts platforms.

Used for furniture, work table, and countertop. Mobile platforms for scenes or audiences.

Used for floating cover for the oil tank.

Used for solar energy panels.

Used for bus stop shelter, sunshade, and awning platform.

Used for the platen, fixture, and infill panels.

Used for machine enclosure, machining surface.

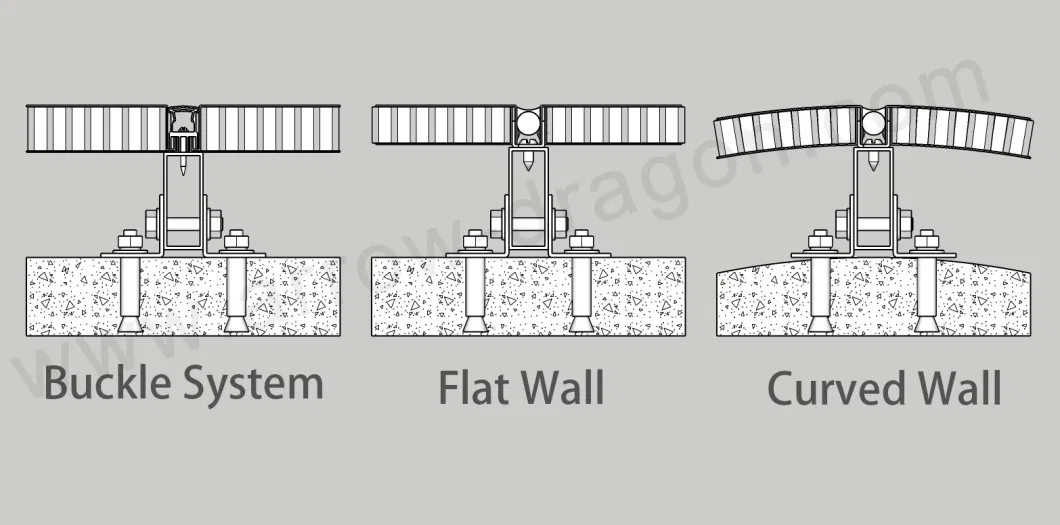

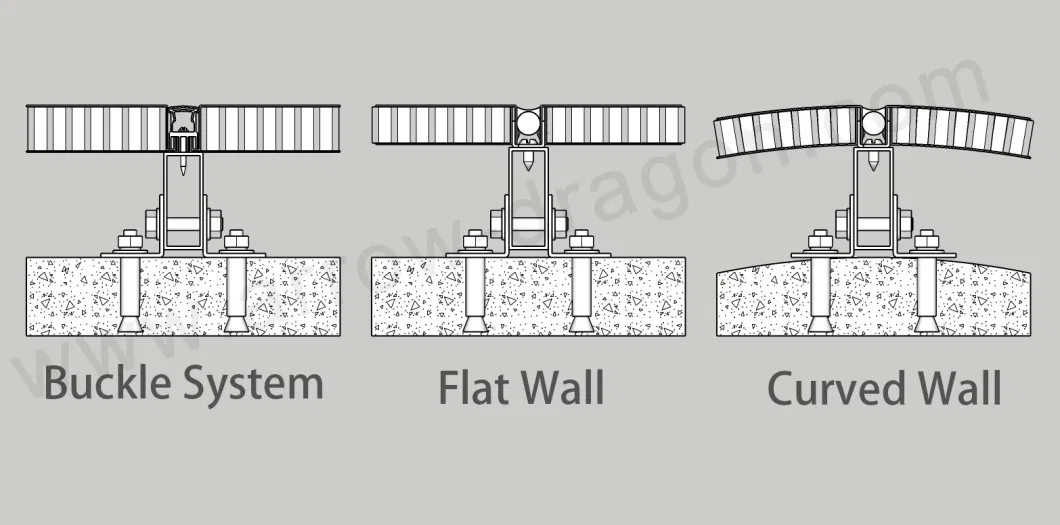

Installation Diagram

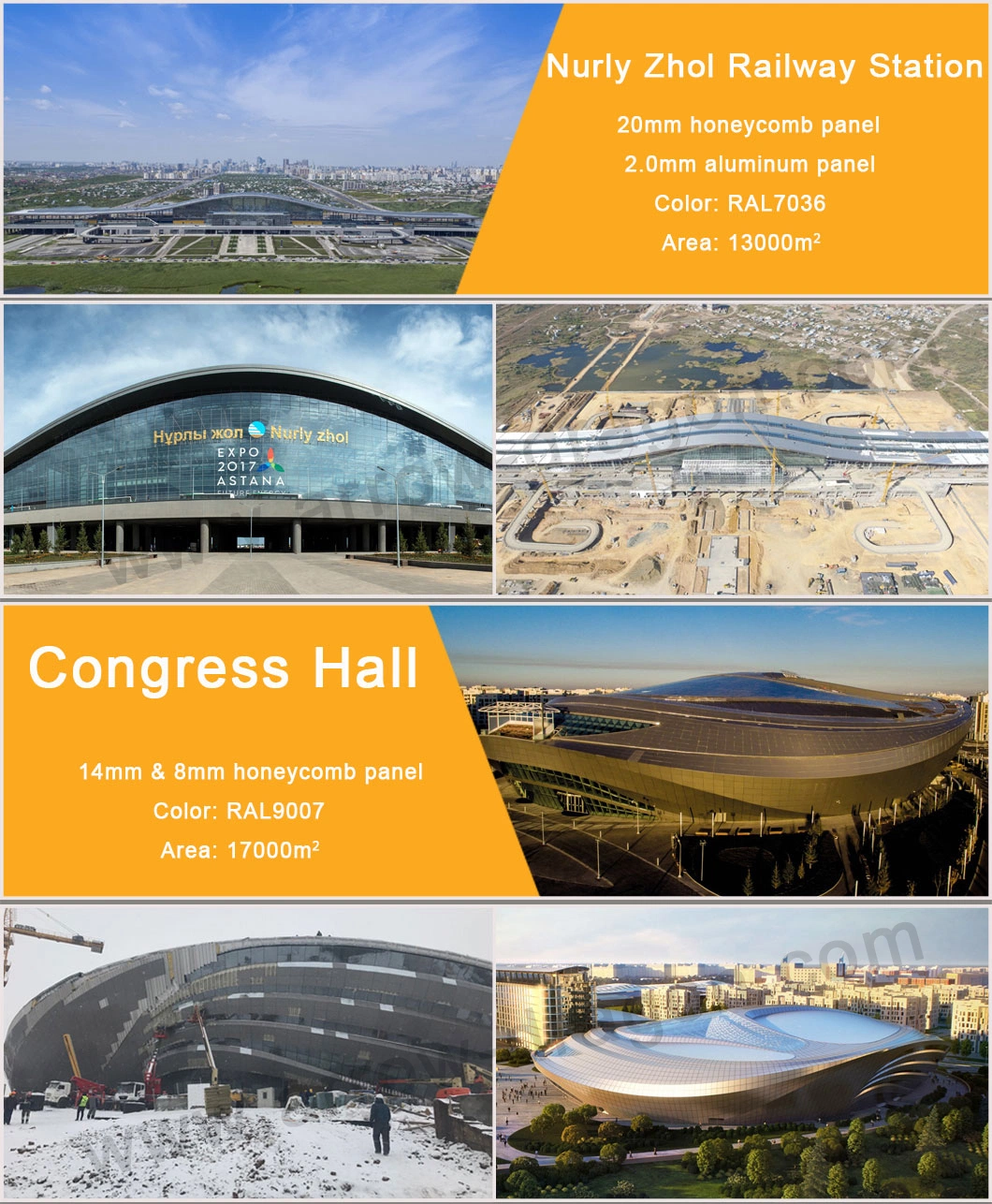

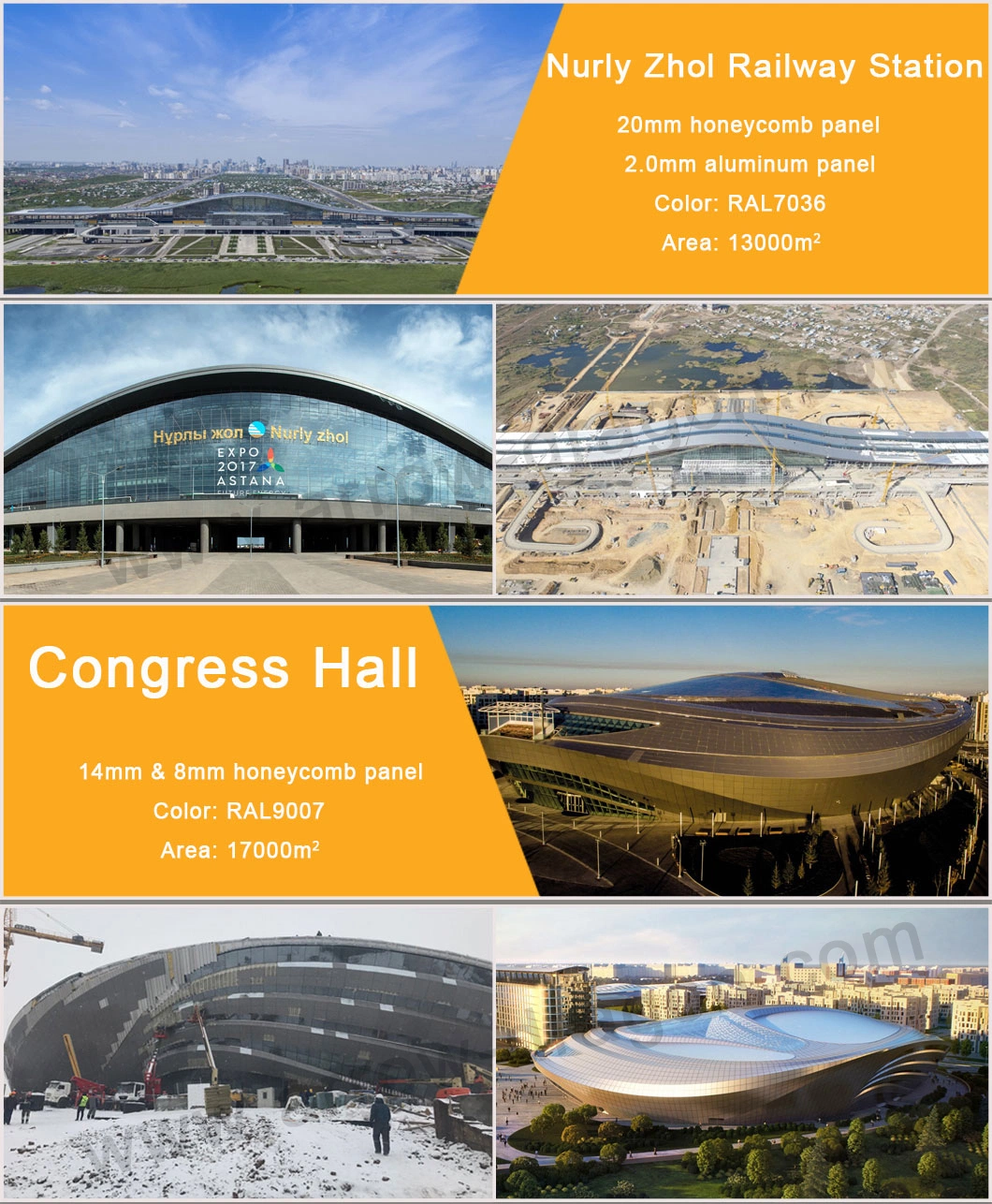

Projects Reference

International Exhibition

FAQ

Arrow Dragon Metal Products Co., Ltd specializes in aluminum panels, including regular wall panels (solid aluminum panels, perforated/laser cut panels), curved panels (single curved/double curved/twisted panels), honeycomb panels (aluminum/stone aluminum honeycomb panels), expanded mesh, screen panels, and honeycomb core (aluminum/s.s./mild steel honeycomb core). Due to our outstanding metalwork and stable coating quality, our products have been approved by architects and used in many big projects (pls find it in below Projects Reference).

Aluminum honeycomb panels are made of high-quality aluminum plates, and apply roller coating/powder coating on the surface, the panels can be prevented color fading and corrosion from UV, high temperature, humidity, and atmospheric erosion.

Our 6 Main Products

Specification of Aluminum Honeycomb Panel

| Aluminum alloy | Aluminum alloy 5052/3003 |

| Temper | H24 |

| Honeycomb panel thickness | 3.5-300mm |

| Dimension | Width: up to 2000mm Length: up to 16000mm |

| Aluminum face sheet | Thickness: 0.5-1.2mm |

| Aluminum base sheet | Thickness: 0.5-1.2mm |

| Honeycomb core | Aluminum alloy 3003 H24 Cell size: 1/2inch, 1/4inch, 3/8inch Foil thickness: 0.04mm, 0.05mm, 0.06mm, 0.07mm |

| Adhesive | Polymer adhesive film Bio-component modified epoxy resin. Bio-component modified polyurethane |

| Coating | Fluorocarbon roller coating PE coating Powder coating |

| Color | Pure white, Metallic color, RAL & Pantone Color |

| Special color | Wooden grain and stone grain |

Coating Layer Composition of Roller Coating and Powder Coating

Features of Aluminum Honeycomb Panel

- Extremely lightweight.

- Excellent strength, good rigidity, and super stiffness.

- High resistance to moisture and corrosion.

- Fire resistance and shockproof.

- Heat insulating and soundproof.

- Easy to be processed into any artistic designs or unique shapes.

- Easy and safe for installation.

- Diversity color choices bring an elegant decorative effect.

- Cost efficiency.

- Recyclable, friendly to the environment.

Workshop Show

Production Procedure

Sheet metal procedure

Cutting/Shearing - Punching - Arcrolling - Bending - Welding - Burnishing - Rib Assembling - Rivet Assembling - Polishing - Spray Coating.

Spray coating procedure

Hanging - Skim - Alkali - Elimination (by acid) - Chromizing - Drying - Spraying Coating - Baking - Inspection.

Compositing procedure

Gluing - Core Compositing - Sheet Compositing - Vacuum Pressing

Package & Delivery

Application

Aluminum honeycomb panels are widely used in our daily life, not only in architecture area but also in transportation and other areas.

Architecture areas:

Used for architecture: curtain wall, façade cladding, ceilings, roofing, soffit, and column cover of the buildings.

Transportation areas:

Used for cruise ships, fast ferries, luxury marine, yachts and other special vessels.

Used for the rail vehicle, lorry, cabins, and flap systems.

Other areas:

Used for the cleanroom, lightweight containers, carbines for the machine tool, wind tunnels, and lifts platforms.

Used for furniture, work table, and countertop. Mobile platforms for scenes or audiences.

Used for floating cover for the oil tank.

Used for solar energy panels.

Used for bus stop shelter, sunshade, and awning platform.

Used for the platen, fixture, and infill panels.

Used for machine enclosure, machining surface.

Installation Diagram

Projects Reference

International Exhibition

FAQ