Basic Info.

Model NO.

GM-SB-76CNC

Applicable Material

S. S., M. S., Copper, Aluminium, Alloy, Galvanized

Applicable Shape

Round, Rectangle, Square, Oval, Solid Bar, Profile

Warranty

2-Year

Certificate

ISO9001: 2000

Technical

Draw Bending/Drawing Bending+Booster/Rolling

Cooling System

Water Cooling/Fan Cooling

Machine Color

Our Standard/Customised

Waterproof Rating

Ipx-8

Condition

New

Certification

ISO 9001:2000, CE, UL

Suitable for

Copper, Aluminum, Alloy, Carbon Steel, Ss

Transport Package

Iron Frame/Wooden Case

Specification

CE

Trademark

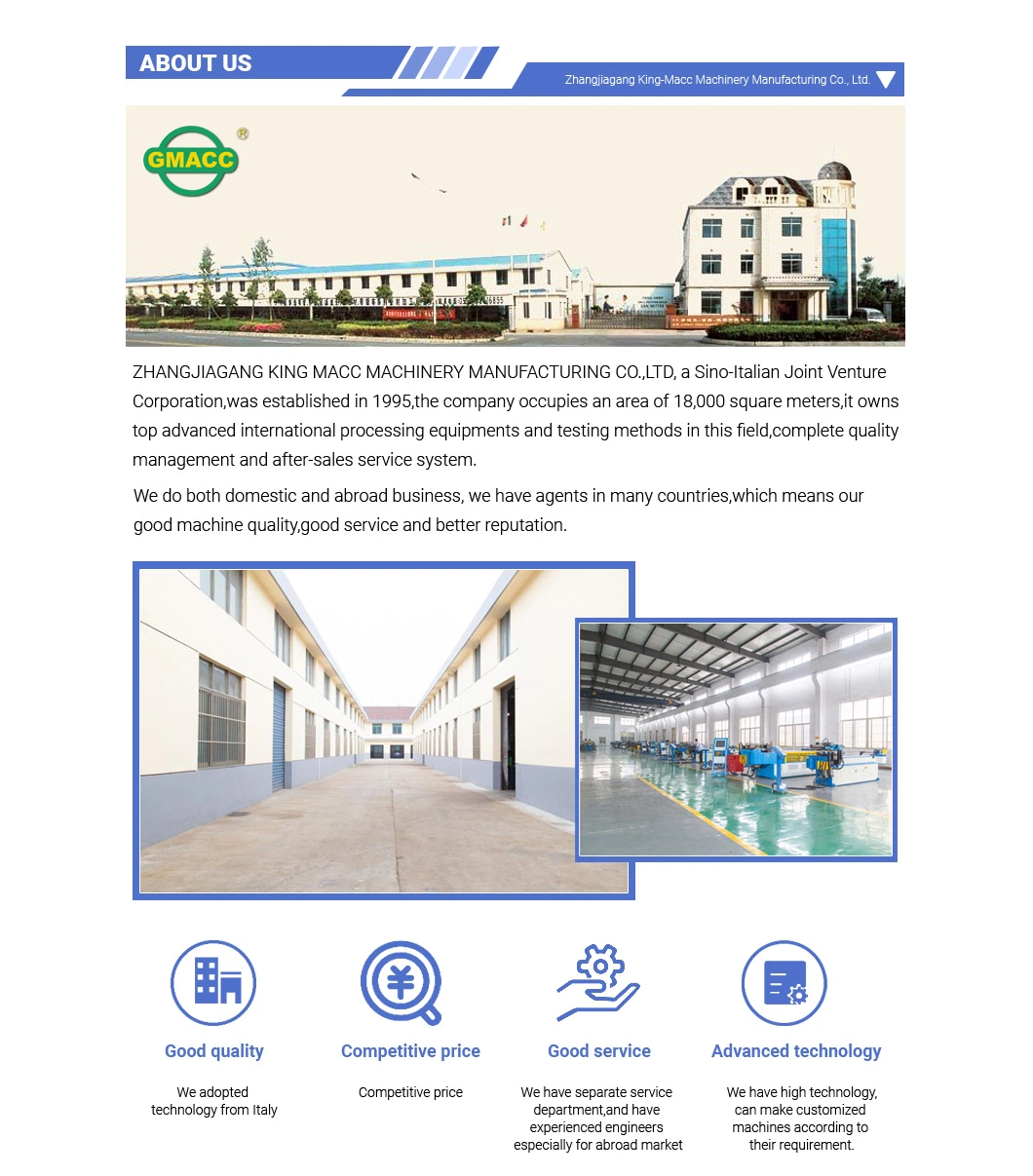

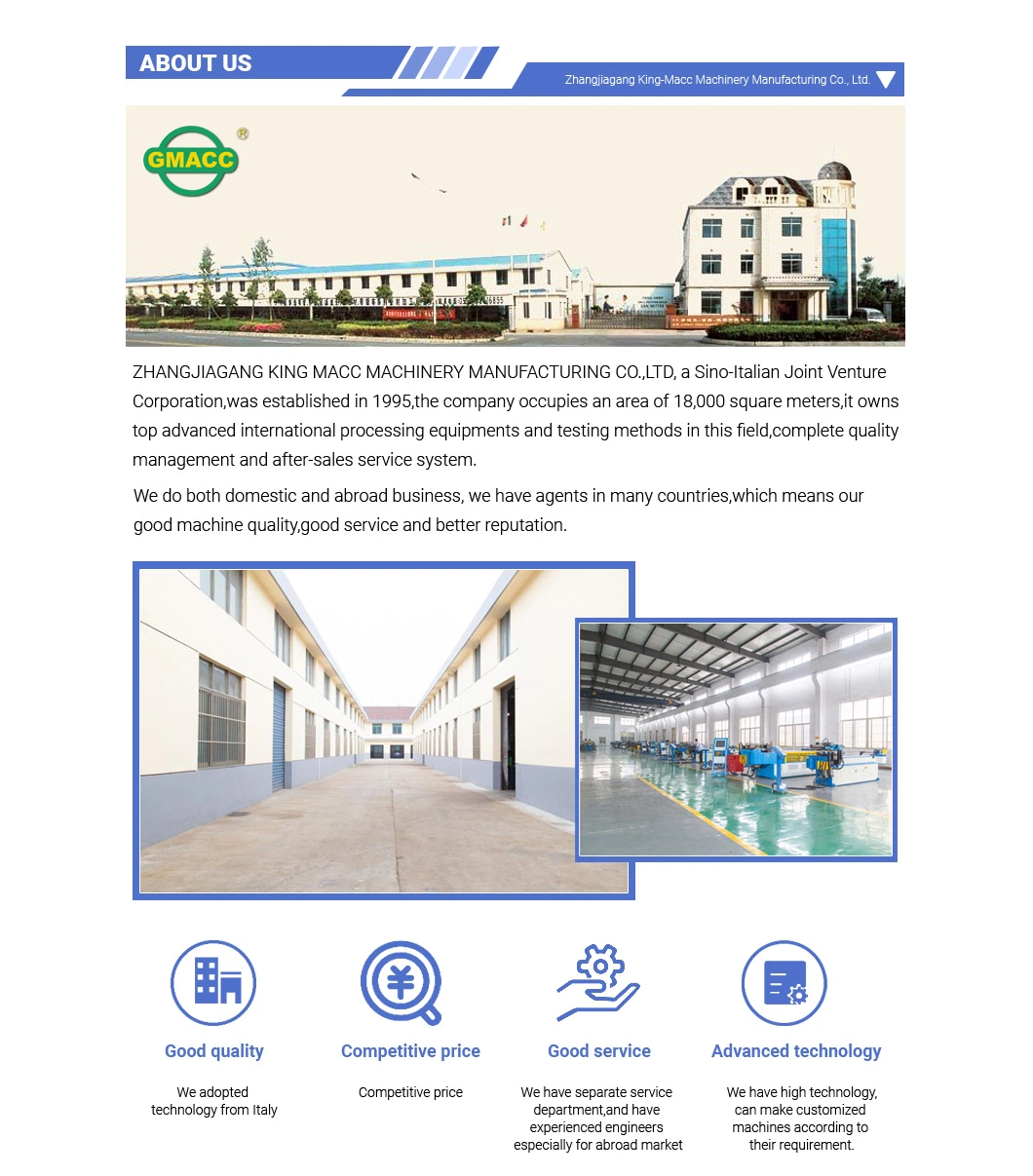

GMACC

Origin

China

HS Code

8462219000

Production Capacity

5000PCS/Year

Packaging & Delivery

Package Size

480.00cm * 120.00cm * 135.00cm

Package Gross Weight

3500.000kg

Product Description

GM-SB-76CNC Full-Auto Numerical Control

Model:76×2A×1S

Model:76×2A×1S

- Machine Characteristics

- Main Technical Parameter

| Name | Unit | Parameter |

| Mild steel round tube | mm | ¢76*4 |

| Stainless Steel | mm | ¢76*3 |

| Light alloy annealed round tube | mm | ¢76*6 |

| Mild steel square tube | mm | 60*60*3 |

| Mild steel rectangular tube | mm | 65*55*3 |

| Mild steel round solid bar | mm | ¢35 |

| Mild steel square solid bar | mm | 30*30 |

| Min. bending radius | mm | 30 |

| Max. Bending radius(Standard) | mm | 350 |

| Head overhang (on bending centre) | mm | 600 |

| Head height (on bending centre) | mm | 580 |

| Bending centre height (from floor) | mm | 1060 |

| Max. bar passage inside the P.O.B. positionner | mm | 50 |

| Clamping adjustable stroke | mm | 0-136 |

| Shouldering adjustable stroke | mm | 300 |

| Mandrel retraction adjustable stroke | mm | 0-136 |

| Max. Bending Angle | ° | 190° |

| Through Effective Distance | mm | 4000 |

| Bending Speed(Max.) | °/sec | 30 |

| Max. rotation speed (axis Z) | °/sec | 160 |

| Max. feeding speed (axis X.) | mm/sec | 800 |

| Bending angle Precision | ° | ±0.10 |

| Rotation angle Precision - axis Z | ° | ±0.10 |

| Shifting Precision - axis X | mm | ±0.10 |

| Rotation Servo Motor Power | KW | 1.5 |

| Feeding Servo Motor Power | KW | 1.5 |

| System Motor Power | KW | 7.5 |

| Hydraulic Pump Volume | L | 23 |

| Max. Pressure | Mpa | 16 |

| L*W*H (Packaging Dimension) | mm | 5000*1200*1350 |

| Machine Weight | T | ABOUT 3.5 |

- Configuration of Hydraulic and Electronic Control System

| Name | Manufacturer |

| Hydraulic Motor | Germany Siemens(Beide)or Runmali |

| Hydraulic Pump | Wuxi Tuoli |

| Hydraulic Valve | Japan Yuken(Imported) |

| Oil way Board | Taiwan Shanghong (Imported) |

| Cylinder | Shanghai Qifan |

| Touch screen | Taiwan Weinview(Imported) |

| PLC | Japan Mitsubishi(Imported) |

| Servo Motor | Japan Mitsubishi(Imported) |

| Angle controller | Japan Nemicon(Imported) |

| Transformer | Wuxi Xinyu |