Basic Info.

Model NO.

ST-W12

Side Rolls Diameter (mm)

220 mm

Top Roll Diameter (mm)

280 mm

Lower Roll Diameter (mm)

260 mm

Max. Pre-Bending Thickness (mm)

12 mm

Color

Can Be Customized

Material Yield Limit (MPa)

245

Voltage

380V

Transport Package

Plywood Package

Specification

4200mm × 1550mm × 1550mm

Trademark

SAMET

Origin

Jinan Shandong

Production Capacity

200sets/Month

Product Description

Product Description

Introduction

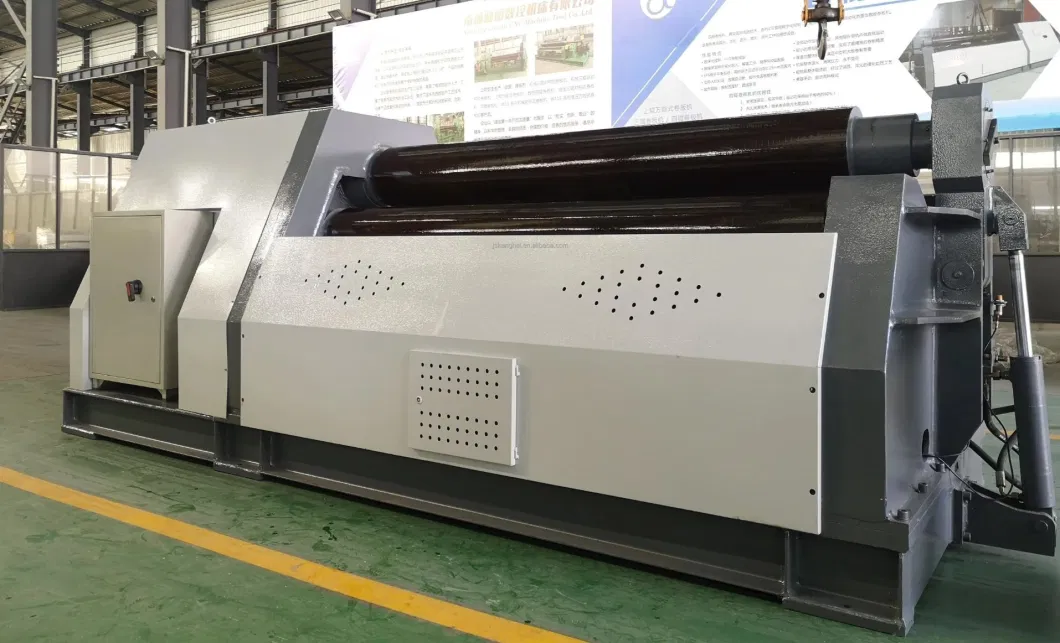

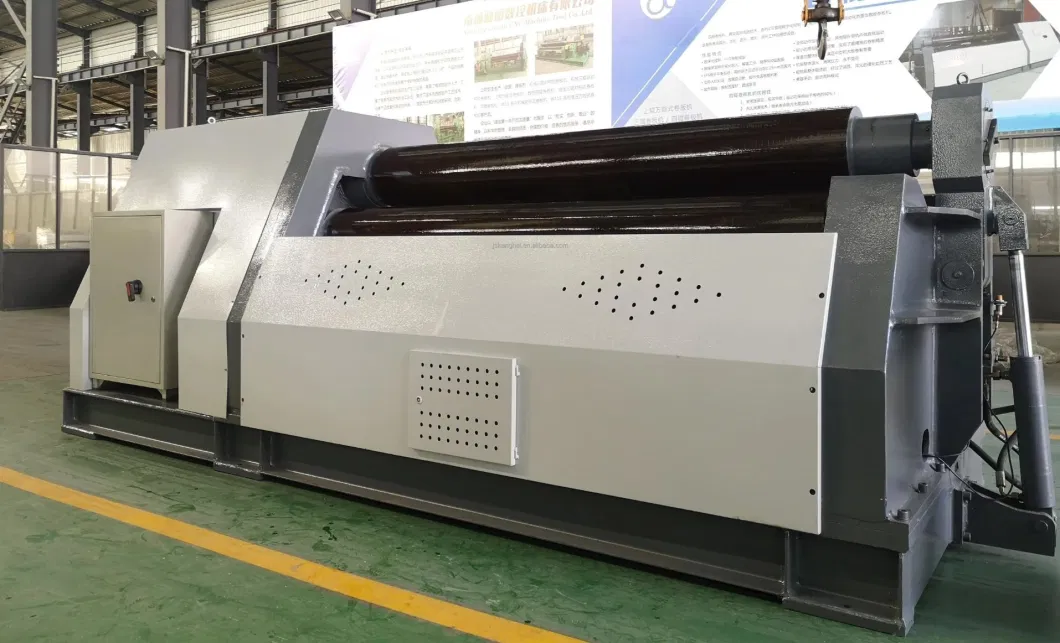

This machine is a CNC plate rolling machine with internationally advanced technology, programmable digital control by PLC, fully hydraulic drive, and automatic rolling. It is an ideal processing equipment for rolling circular, curved, and conical workpieces.

Features

1. Fully hydraulic drive, efficient and energy-saving

2. One time to finish the process of pre-bending and rolling without turning direction

3. Top roll as the drive roll driven by hydraulic motor

4. Side rolls moving up and down along an oblique straight line while lower roll rising up and down vertically

5. Absolute value encoders on both sides of the pressure rolls to control synchronization

6. Permanent lubrication technology, and no need to add lubricating oil during the bearing lifespan

7. Adjustable clamping pressure without slipping

8. Can roll a cylinder whose diameter could be 1.3 times the diameter of the top roll

2. One time to finish the process of pre-bending and rolling without turning direction

3. Top roll as the drive roll driven by hydraulic motor

4. Side rolls moving up and down along an oblique straight line while lower roll rising up and down vertically

5. Absolute value encoders on both sides of the pressure rolls to control synchronization

6. Permanent lubrication technology, and no need to add lubricating oil during the bearing lifespan

7. Adjustable clamping pressure without slipping

8. Can roll a cylinder whose diameter could be 1.3 times the diameter of the top roll

Specification

| Number of Rolls | 4 |

| Maximun Plate Width | 2000mm |

| Max. Plate Thickness | 16mm |

| Max. Pre-bending thickness | 12mm |

| Top Roll Diameter | 280mm |

| Lower Roll Diameter | 260mm |

| Side Rolls Diameter | 220mm |

| Brand Name | SAMET |

| Motor Power | 15KW |

| Machine Overall Dimensions | 4200mm × 1550mm × 1550mm |

Detailed Images

Working Rolls

Unloading Device

PLC Control System

Main Motor and Hydraulic Station

Hydraulic Motor

Hydraulic Oil Cylinders and Proportional Valve

Product Parameters

| |