Basic Info.

Model NO.

HZF-674

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.01mm

Customized

Customized

Size

Customized

Delivery Date

15-30 Days

Weight

0.1kg-50kg

Tolerance

+/- 0.01mm

Transport Package

Crate or Plywood Case or as Customers′ Request

Specification

SGS/ISO

Trademark

HZF

Origin

Shandong, China

HS Code

84089452

Production Capacity

50000 PCS/Month

Product Description

Product Description:

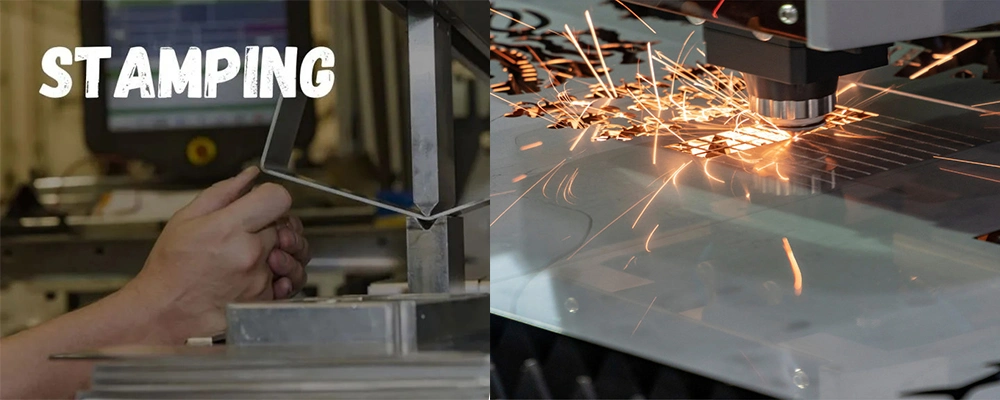

| Process | 1. Progressive Die 2. Depth Drawn 3. Compound Die 4. Single Punch 5. Robert Welding /Laser Welding/ Butt Welding / Spot Welding 6. Passivate Or Phosphate Coating 7. Laser Cutting 8. Bending 9.Assembly | ||||||||

| Material Thickness | 0.5mm ~20mm, or Other Special Available | ||||||||

| Material | 1. Carbon Steel: DC01, DC03 DC04, 1008, 1010, Q235, SPHE, SPCC 2. Alloy Steel: SAPH440; QSTE 340; Q345B 3. Aluminum SAE3003-0, SAE3005-H66 4. Stainless Steel 304SS, 316SS, 301SS 5. Copper T1, T2, Brass H57, H59, H59-1, H65 6. Silicon Steel Sheet | ||||||||

| Surface Treatment | 1.Powder Coating 2. Zinc Plating 3. Anodization 4. Nickel or Chrome Plating 5. Golden or Silver Plating 6. DACROMET 7. Electrophoresis 8. Fe/Zn+Ni 10μ P1 | ||||||||

| Tooling Capability | 1. CNC Center 2. Sodick Wire 3. Electric Spark 4. High Speed Punch 5. Grinding Machine 6. CNC Milling Machine | ||||||||

| Our Facility | 1.Stamping Machine from 16T to 500T 2. High speed Punch from 45T to 200T 3. Hydraulic Machine from 80T to 250T 4. Numerical Control 5. Auto-feeder Turret Punch Press 6. Press Brake 7. Robot Welding 8. Laser welding Machine 9.Butt welding Machine | ||||||||

| Quality System | 1. ISO9001 2. TS16949 3. ISO14000 4. SGS Certification 5. SPC or CMK 6. MSA 7. CP 8. FEMA 9. APQP | ||||||||

| Design | 3D: Solidworks,UG and AutoCAD | ||||||||

Company Introduce:

We Qingdao Haozhifeng Machinery Co.,Ltd, is a leading enterprise, specializing in mechanical parts of torque for bushing with different size and material. Torque rod bushing is mainly used in mechanical system as auto, truck, tractor and so on which demand torque rod bushing spare part. With high metal strength, torque rod bushing works long hours. Coated with kinds of surface treatment of environmental fluid, torque rod bushing obtains strong mechanical properties and resistance to corrosion.

Product Inspection:

Inspection: in-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: three-coordinates measuring machine,hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper, etc.

FAQ

1. How can I get the quotation?

Please send us information for quote : drawing, material, weight, quantity and request.

2. How long will be taken for sample production ?

Sample: 20-30 days for making mold and sample production . The accurate time depends on your product.

3. Can you accept Mini order ?

Yes . Mini order and trial order can be acceptable .

4. What is your Payment Term ?

Mold cost : 100% TT advanced.

Main order: 40% deposit, balance 60% to be paid against the copy of B/L .